Sahiba Cuccria

8 mins read

10 mins read

Raheel Ladak has over eight years of hands-on freight logistics experience across LTL and FTL networks. He works with businesses to uncover cost-saving opportunities, optimize carrier selection, and streamline cross-border shipping processes for scalable growth.

You've just got a huge order from Canada. Your customer is excited, your profit margins look great, and everything seems perfect. Then suddenly you are hit with custom delays around Canada or the US.

Shipping delays across borders have become the silent profit killer for most of the sellers. One delayed shipment can cost you more than just money – it damages trust and future sales.

But the good news is, most international shipping delays are predictable and preventable. Once you understand the common causes, you can avoid border delays like a pro.

This blog will further walk you through 10 cross-border shipping delays and guide you how to handle delays in delivery situations.

Shipping delays 2026 are hitting harder than ever. Border crossings that used to take hours now stretch into days. What changed?

First, shipping issues today stem from outdated systems trying to handle modern volumes. Second, new regulations pop up faster than you can track them. One day your products pass through customs. The next day, they need three extra forms you've never heard of.

Third, everyone's shipping more products internationally. eCommerce exploded, and cross-border trade followed. The infrastructure? Still progressing.

The result? You get disappointed customers and lots of unexpected costs.

But don't panic. By understanding the below given causes and solutions, you can learn the rules, build better relationships, and avoid shipping delays.

CTA: Delays don’t wait. Neither should you. eShipper keeps your cross-border shipments move without any shipment delays. Start Today!

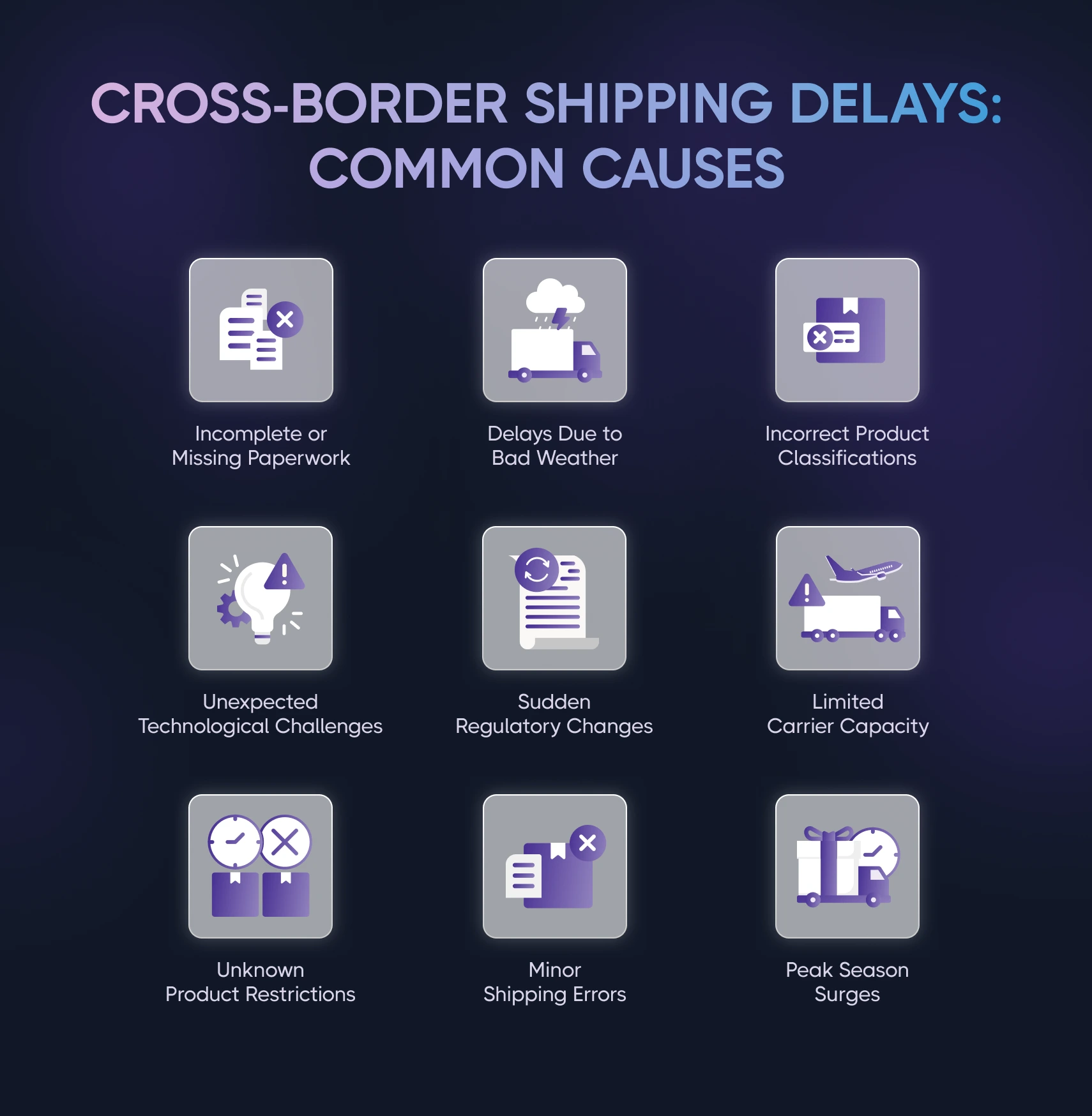

Tired of shipments getting held up in the borders? Discover the 10 common causes behind cross-border shipping delays and solutions to prevent them.

Customs delays in Canada and the US usually start with paperwork problems. Missing forms, wrong codes, or incomplete information can cause shipping delays.

Commercial invoices are the biggest cause:

Value declarations must match actual prices paid, not retail prices. Country of origin labeling creates confusion too. "Made in China" parts assembled in Mexico need specific documentation. Mixed-origin products require detailed breakdowns of each component's source country.

Solution: Prepare a complete customs checklist for each shipment. Create a master database of your items, including harmonized codes, country of origin information, and standard descriptions. This prevents mistakes during busy periods.

For commercial invoices, use a standardized template that includes all required fields. Work with a licensed customs broker if you ship regularly to Canada/US – they charge around $50-150 per shipment but save you thousands in delay costs.

Nature doesn't care about your shipping schedule. Sometimes, snowstorms shut down border crossings and hurricanes close ports.

Winter months hit Canada-US routes especially hard. Summer brings different challenges like the heat waves affecting cargo handling times, while thunderstorms create flight delays.

Solution: Create seasonal shipping calendars that account for typical weather patterns. Schedule critical shipments during historically stable weather windows. Make sure to:

Using wrong harmonized codes can trigger automatic inspection holds. Each product needs the correct classification to clear customs smoothly.

A lot of sellers use generic or broad categorization rather than specific codes.

Example: A "Men shirt" may have dozens of different codes depending on the material, manufacturing process, and intended usage. Wrong codes result in your package being pulled for manual examination, which causes unnecessary shipping delays.

Solutions: Invest time in conducting proper product classification research. Find accurate codes for your products by searching the official Harmonized Tariff Schedule database. When in doubt, contact customs brokers who specialize in your product category.

Create a product classification database that includes photographs, descriptions, and confirmed codes. Update it regularly as regulations change. Train your shipping team to double-check classifications before submitting paperwork.

Sometimes, unexpectedly some customs systems crash. When technology goes down, everything stops. Manual processing takes 10 times longer than electronic submissions. Integration problems between different systems cause additional problems.

Solutions: Maintain detailed paper documentation for all electronic submissions. Create digital backups stored in multiple locations using cloud storage services. Create direct communication channels with your logistics partners' technical support teams.

Trade regulations change constantly. New product restrictions appear overnight. Classification requirements change without any warning.

USMCA rules get updated regularly. Tariff schedules change quarterly. Product safety standards evolve based on new research and incidents.

A recent example: In March 2025, the US implemented 25% tariffs on Canada and Mexico, then just two days later announced USMCA-compliant products would be exempt. This rapid change caught many shippers off-guard, highlighting why real-time monitoring is now essential.

Solutions: You can subscribe to official government regulatory alert services from both US and Canadian customs agencies. Also, join industry trade associations that specialize in your product categories.

Not enough trucks. Limited flight space. Overbooked shipping schedules. When carriers hit capacity, your shipments wait.

Driver shortages affect the entire trucking industry. Experienced cross-border drivers need special training and security clearances. Many retired during the pandemic and weren't replaced. Air freight faces similar constraints with reduced passenger flights cutting cargo space.

Solutions: Diversify your carrier partnerships to include multiple ways of transportation. To avoid single-point failures, use at least three distinct carriers when shipping across borders. Negotiate volume agreements with carriers during off-peak seasons to ensure availability during busy periods.

Split your shipments strategically across carriers based on product characteristics. For example, send time-sensitive electronics via air freight with FedEx, route bulk household items through ground transport with UPS, and use DHL for international express deliveries that need specialized handling.

CTA: Need reliable cross-border shipping - even during peak season? eShipper connects you with multiple carriers and custom solutions that grow with your business. Get an Instant Quote!

Some products need special permits. Others face seasonal restrictions. A few are banned entirely between certain countries.

Food items have strict rules. Electronics need certifications. Even clothing can face restrictions based on materials. Agricultural items experience the most thorough examination, with phytosanitary certificates and ingredient statements are essential.

Solutions: Before you begin selling overseas, compile a complete product compliance database. Use government websites and trade resources to learn about import rules in each destination country.

Use the Harmonized Tariff Schedule (HTS) lookup tools to ensure that product classifications are valid. Build contacts with regulatory experts who are specialized in your product categories.

Below are some examples of seasonal restricted products:

| Product Type | Restriction Period | Reason | Alternative Actions |

| Live Plants | Winter months (Dec-Feb) | Freeze damage, dormancy | Ship in spring/summer only |

| Fresh Produce | Varies by crop | Harvest seasons, pest control | Check CFIA seasonal calendars |

| Fireworks | Year-round restrictions | Safety regulations | Requires special permits |

| Hunting Equipment | Hunting season dependent | Wildlife protection | Coordinate with local seasons |

Wrong addresses stop shipments. Typos in names cause delays. Missing phone numbers frustrate delivery drivers.

These seem like small errors, but they create big problems when handling delay in delivery situations. Address formats differ between countries – US addresses put state before ZIP code, while Canadian addresses put province after postal code. Name variations like "John Smith" vs "Jonathan Smith" can cause confusion and shipping delays.

Solutions: Create shipping checklists to verify every address, phone number, and name before shipping. Use address validation tools if you ship frequently to catch errors before they become problems.

Holiday seasons crush shipping systems. Peak rushes like Black Friday or Christmas sales overwhelm carriers.

Your regular 3-day shipping becomes 10-day shipping. Customers get frustrated. You have a high chance of losing sales to competitors. November through January creates the perfect storm with holiday shopping peaks, worsening weather, and staff vacations.

Solutions: Plan peak season shipping months in advance. Book carrier space early and set realistic customer expectations. Consider alternative shipping windows – ship early November instead of late December.

Customs duties need payment before release. Credit card systems crash. Currency conversion takes forever.

Different countries use different payment methods. Canada accepts electronic transfers while Mexico requires certified checks. Currency fluctuations complicate calculations with exchange rates changing hourly.

Solutions: Set up multiple payment methods for customs duties. Have backup credit cards ready and consider prepaid customs accounts for frequent shipments. Work with logistics partners who handle payment processing with better systems than individual shippers.

Cross-border cargo theft has become a serious concern for Canada-US shippers. What used to be random opportunistic theft has become an organized criminal operation targeting high-value shipments during border crossings.

Shipping delay news always focuses on problems. Let's talk solutions instead.

First, communicate early and often. Don't wait for customers to ask about delays. Reach out first with updates and realistic timelines. Be honest about what you know and don't know. Customers appreciate transparency more than false promises.

Second, have backup plans ready. Know alternative shipping routes. Keep emergency carrier contacts handy. Build flexibility into your operations.

Third, learn from every delay. Track causes and solutions. What worked? What didn't? Use this data to improve your processes.

How do you explain shipping delays to customers? Start with empathy. Acknowledge their frustration. Then provide specific information.

Instead of "Your shipment is delayed," say "Your shipment is held at customs for documentation review. We expect a release by Friday and delivery by Monday."

Offer alternatives when possible. Expedited shipping, partial shipments, or temporary substitutions can keep customers happy. Set up automatic update systems – customers want information without having to ask for it.

International shipping delays will always exist. Weather happens. Systems crash. Regulations change. That's business reality.

But smart sellers don't let delays control their success. They plan ahead, build relationships, and stay flexible. The key is turning delays from disasters into minor inconveniences.

Start with one or two solutions from this blog. Master those, then add more. Small improvements will help you yield big results. Your cross-border shipping doesn't have to be a nightmare - with these strategies, it can become a competitive advantage.

Start with empathy and provide specific details about shipping delays cross-border. Instead of saying "delayed," explain "Your package is held at customs for documentation review, expected clearance Friday." Always offer alternatives or next steps.

Create a step-by-step action plan before delays occur. First, identify the delay cause and get realistic timelines from carriers. Immediately notify customers with specific details about customs delays Canada US.

Contact carriers immediately for detailed explanations and realistic resolution timelines. Document the cause, resolution, and prevention steps. Keep customers informed throughout the process while building stronger logistics relationships for future success.