Sahiba Cuccria

8 mins read

16 mins read

Raheel Ladak has over eight years of hands-on freight logistics experience across LTL and FTL networks. He works with businesses to uncover cost-saving opportunities, optimize carrier selection, and streamline cross-border shipping processes for scalable growth.

Sustainable shipping builds tomorrow's brands

In 2026, from being “eco-conscious,” consumers have gradually become “eco-critical.”

Sustainability is not just a trendy movement to support anymore. It dictates the present and future of the environmental systems and processes.

In fact a 2024 IBM survey revealed that 73% of Gen Z consumers consider sustainability a key factor in their buying decisions. Even more are telling that 57% are willing to change their purchasing habits to help reduce negative environmental impact.

In other words, your shipping practices are no longer behind-the-scenes logistics. They’re front and center in your customer experience.

Your buyers care about how their package arrives, never would you have anticipated this in a million years now, would you?

From the packaging materials used to the carbon footprint of delivery routes, every aspect matters. Buyers are increasingly scrutinizing how their orders are fulfilled, whether companies use recyclable materials, minimize waste, or adopt greener logistics.

So, “Sustainability” is far from being a marketing buzzword in this time and age. It is something sellers like you must prioritise in order for your brand to represent the right causes, target an increased number of audience and retain them as loyal customers.

Let’s dive into how a sustainable packaging and shipping process can become a game-changer for sustainability.

Sustainable shipping refers to practices, technologies, and policies that reduce the environmental impact of transporting goods. At its core, it’s about making smarter, cleaner choices at every step of the shipping journey.

It is simply the right measures to take in order to reduce greenhouse gas emissions (GHGs) like CO₂, methane, and nitrous oxide.

Additionally, air and water pollution, packaging waste, fuel consumption and energy inefficiencies also fall under the same category.

From eco-friendly packaging to efficient logistics planning, sustainable shipping looks at both big-picture and day-to-day actions to lower a brand’s footprint.

Sustainability in 2026 has become a non-negotiable. More than it being extremely crucial to implement, it is collectively becoming a choice consumers are now mindfully making. Keeping up with this need is the same as keeping up with all the other needs of customers, like premium products, fast delivery, etc.

Governments across the globe are mandating stricter emissions targets:

The European Union’s “Fit for 55” package demands a 55% reduction in GHGs by 2030, with heavy emphasis on transport emissions.

The U.S. Environmental Protection Agency (EPA) has introduced new emissions standards for trucks and delivery vehicles, set to take effect by 2027, but many companies are expected to comply early.

Shipping giants like Maersk and CMA CGM have committed to net-zero emissions by 2040, pushing downstream pressure onto smaller sellers and freight customers.

Let’s look at what makes green shipping and sustainability such a vital deal in 2026.

With more and more people coming forward to support environmental causes and the highly opinionated consumers are all for sustainability. Social media buzzing with “sustainability” written all over it, stores producing paper bags instead of plastic and drinks being served with paper straws over plastic.

Well, this didn’t just stop at that. It has become equally important to maintain the same practices for e-commerce shipping solutions as well. As in, making use of recycled cardboard, reused boxes, eco-friendly packaging, handmade papers, etc.

With more and more consumers choosing brands that sell sustainable goods, they have also started to support brands that truly follow these sustainable practices.

Governments across the globe are mandating stricter emissions targets:

The European Union’s “Fit for 55” package demands a 55% reduction in GHGs by 2030, with heavy emphasis on transport emissions.

The U.S. Environmental Protection Agency (EPA) has introduced new emissions standards for trucks and delivery vehicles, set to take effect by 2027, but many companies are expected to comply early.

Shipping giants like Maersk and CMA CGM have committed to net-zero emissions by 2040, pushing downstream pressure onto smaller sellers and freight customers.

The ESG (Environmental, Social, and Governance) movement has evolved significantly. Investors now use sustainability KPIs to assess long-term viability. Sustainable shipping companies are being prioritised on a higher level than ordinary ones.

At the same time, marketplaces like Amazon and Walmart are raising the bar for sellers by increasing supply chain standards. This includes emissions, packaging waste, and overall environmental impact.

Amazon requires sellers to meet Climate Pledge Friendly standards (e.g., OEKO-TEX, Fair Trade) and reduce packaging waste via Frustration-Free Packaging.

On the other hand, Walmart asks suppliers to join Project Gigaton (cut 1B tons CO₂ by 2030), report via CDP, and follow its Sustainable Packaging Playbook.

Vendors are being convinced to follow and progress in maintaining high sustainability standards in order to comply with the platform's status.

Businesses that fail to prioritize sustainable shipping risk losing access to crucial sales channels and partnerships. Hence, this makes eco-friendly logistics a necessity for everyone in the industry.

Whether you’re a small handmade goods seller shipping 50 orders a month or a multi-national eCommerce brand pushing thousands of SKUs daily, sustainable shipping is actionable and scalable.

Before you can improve your sustainability performance, you need to understand your current impact. Start by mapping your entire shipping footprint, including direct operations and third-party logistics providers.

This includes optimizing energy use, managing waste, and minimizing emissions across every touchpoint in your supply chain.

Calculate your baseline emissions using standardized methodologies like the GHG Protocol. Track fuel consumption, cargo utilization rates, empty mile percentages, and packaging waste.

Many companies discover that packaging alone accounts for 45% of e-commerce emissions, making it a prime target for immediate improvement.

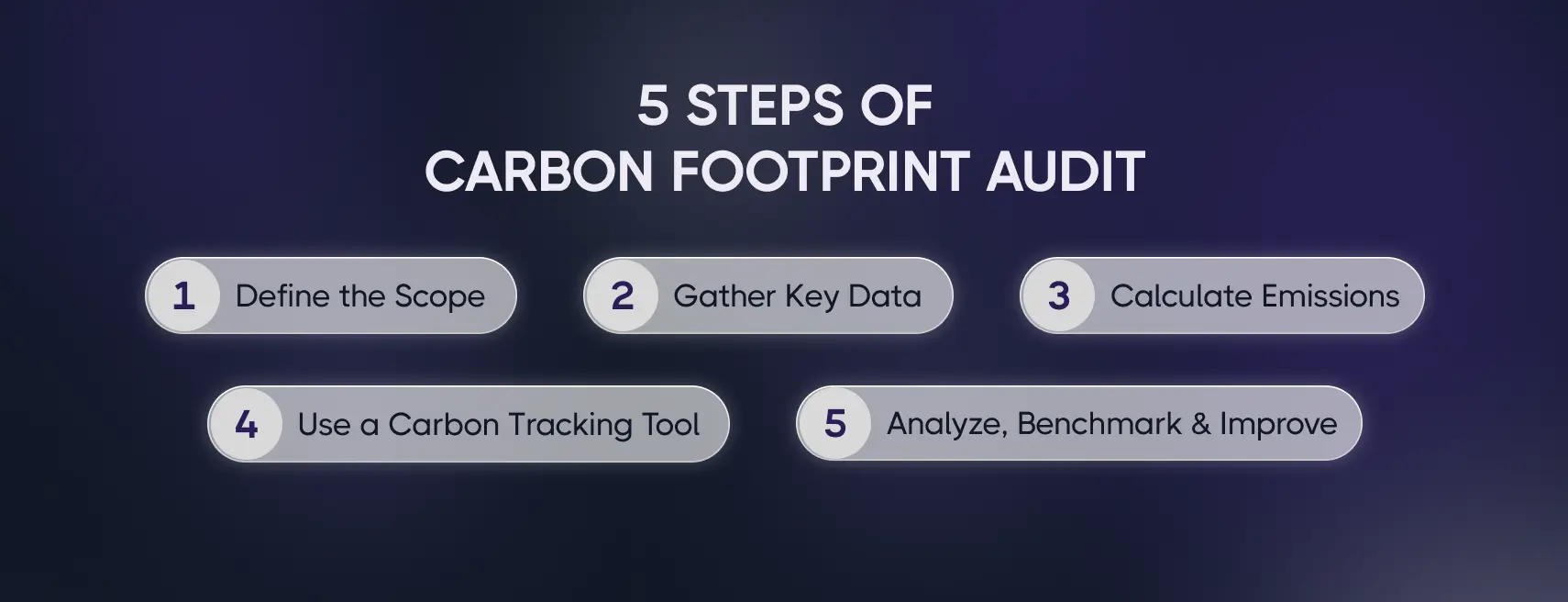

Now, let’s look at how to audit your carbon footprint.

1. Define the Scope

Determine which types of emissions you’ll track:

2. Gather Key Data

Collect shipping and operational data such as:

3. Calculate Emissions

Apply standard emission factors (EPA, DEFRA, GLEC, etc.):

Emissions = Distance × Load Weight × Emission Factor

4. Use a Carbon Tracking Tool

To simplify and standardize the process, use trusted tools like:

5. Analyze, Benchmark & Improve

There you have it, your carbon footprint report!

For example,

Company: Local eCommerce brand delivering in a metro city using vans

Monthly Data:

Step 1: Calculate monthly diesel use

10 litres/day × 25 days = 250 litres/month

Step 2: Apply emission factor (e.g., diesel = 2.68 kg CO₂e/litre)

250 litres × 2.68 = 670 kg CO₂e/month

So, the company emits 670 kg of CO₂e monthly just from one van.

Step 3: Offset or reduce

Switch to electric van = near zero tailpipe emissions

Offset 670 kg CO₂e with a verified carbon credit provider

Impact: Reduces tailpipe emissions to nearly zero.

Example: Replacing the diesel van with an EV doing the same 60 km/day could save 670 kg CO₂e/month

Route optimization represents one of the most immediate and impactful steps you can take. With today’s advanced routing software and fuel management tools, companies are already seeing fuel savings of up to 30%.

And the best part? It doesn’t require a massive investment to get started.

Dynamic routing systems now go far beyond static maps. They blend in real time to weather conditions, traffic delays, port congestion, and even fluctuating fuel prices.

With the right tech in place, your shipping operations can respond with the most efficient path forward.

Utilizing each full container or truck before it goes out, you reduce the number of trips needed. Fewer vehicles on the road, lower emissions, and significant cost savings over time.

Efficient supply chain management systems can make this process seamless.

Switch from diesel to biodiesel or renewable diesel (e.g., B20 or HVO) for a reduction potential of up to 30–80% fewer CO₂e emissions depending on blend.

Let’s take for example, you are based in Southern California, and a storm hits Southern California. Instead of scrambling, your system automatically reroutes trucks around flooded highways and delays.

By the end of the month, you’ve reduced fuel usage by 22%, avoided late penalties, and improved delivery accuracy, without hiring more staff or adding vehicles.

For an upcoming ocean shipment, it recommends slow steaming cutting fuel costs without affecting delivery timelines. Simply reducing a vessel’s speed by 10% can cut fuel consumption by up to 27%.

Your packaging unknowingly falls the biggest prey to carbon emissions. Of course, you must protect your goods with safe packaging like bubble wrap, etc, but there are sustainable choices you can choose to make as well.

You can make use of bio-degradable, eco-friendly packaging materials to drastically reduce the environmental impact of your shipments.

Compostable cornstarch packaging peanuts over plastic pillows, honeycomb paper instead of bubble wrap, recycled cardboard over regular ones, sustainable shipping bags over plastic bags can make a much bigger difference than you’d think.

Additionally, explore reusable packaging systems for appropriate product categories as well.

Ikea switched from Styrofoam to moulded pulp inserts in 2023, reducing their packaging waste by 45% and cutting their packaging costs by $1.2 million annually.

You can also offer “no extra packaging” options at checkout for eco-conscious customers. All this comes together to form a holistic, sustainable shipping packaging for your brand.

Not all shipments need to fly. When speed meets sustainability, mode matters.

Ground shipping is your most eco-friendly option for domestic or regional orders. Use it by default, especially for non-urgent deliveries.

Expedited shipping should be reserved for SLA commitments or exception handling. It’s faster but heavier on emissions than ground.

Air freight is the least sustainable. Use it only for high-value or time-critical orders where delays would cost more than the carbon impact.

Freight pooling, or co-loading, is the practice of combining shipments from multiple sellers into one container or truck. This is an age-old practice to improve load efficiency, reduce the number of trips, and lower transportation costs.

Co-loading helps you share space with others, cutting emissions and saving money without sacrificing delivery times.

It’s a simple way to make your supply chain greener and load efficient.

Coca-Cola and Tesco in the UK have successfully trialed backhauling, where Coca-Cola trucks return with Tesco goods.

Generally, sellers had the practice of using multiple warehouses and storage hubs to stock different SKUs based on categories, demand zones, or exclusivity.

However, in a sustainability-driven era, this elaborate storage system increases overall shipping distance, fuel consumption, and carbon emissions.

Consolidating all your inventory into a centralized FC (fulfillment center) can help reduce unnecessary inter-warehouse transfers, simplify logistics planning, and minimize excess mileage.

This way, orders can be fulfilled from a single node, reducing shipping time, transportation emissions, and operational complexity.

For example, instead of shipping clothing from warehouse A, shoes from warehouse B, and accessories from warehouse C to the same customer, a centralized model can do the same work in one go from a single location.

This not only reduces redundant packaging and multiple carrier routes but also streamlines returns and inventory management, ultimately creating a leaner, greener logistics operation.

Retailers and D2C brands using unified fulfillment centers often see measurable benefits like reduced carbon output per shipment, faster deliveries, and lower last-mile emissions.

Maximize Delivery Coverage in a Single Trip

The way your delivery routes are planned can either multiply your emissions—or drastically reduce them.

A highly effective and sustainable tactic is maximizing delivery coverage within a single one-way route, delivering to multiple drop-off points (e.g., A1, A2, A3, A4, A5) from a central origin (Point A to Point B).

Rather than operating fragmented trips to individual addresses, bundling deliveries along optimized routes ensures that each trip covers the maximum number of orders with minimal detours.

For example, a truck leaving a central hub in Point A can service five localities along a streamlined corridor instead of making five separate return journeys. This drastically reduces fuel consumption, driver hours, and wear-and-tear, lowering both emissions and operating costs.

Smart route optimization platforms now use AI and real-time traffic data to identify the most efficient route clusters.

Some logistics platforms even factor in customer availability, delivery time windows, and vehicle load to fine-tune a near-zero-waste journey.

In short, the more you deliver per trip, the fewer trips you need, and that’s good for both the planet and your bottom line.

Your 3pl provider can make all the difference if you want to drastically alter your packaging. By working with a third-party logistics provider (3PL) that puts sustainability at its forefront or tweaking your logistics operations to promote sustainability, you can go a long way.

Several major shipping companies in North America are increasingly using electric vehicles (EVs) for last-mile delivery and other logistics operations, including FedEx, Amazon, and UPS.

Consider regional logistics hubs to reduce transportation distances. By strategically positioning inventory closer to end customers, you can significantly reduce last-mile delivery emissions while often improving delivery times.

In contrast to old assumptions, sustainability is far from being a profit killer. Rethinking your packaging, routing and fulfillment helps you see a significant shift in your profit margin altogether.

Good sustainability doesn’t have to burn holes in your pocket anymore. It is not just about saving the planet but a tactic to save a decent amount of ROI as well.

Big names have already proven this. Ikea, like I already mentioned, saved over $1.2 million a year just by switching from Styrofoam to molded pulp packaging. That one change cut down waste and shipping costs.

Dell redesigned its boxes to be smaller and recyclable sustainable shipping boxes, which meant they could ship more products per pallet so, less packaging, fewer trips, lower costs.

Even if you're not operating at that scale, small changes still matter.

Tools for route optimization now make it easy as well as affordable for sellers of all sizes to reduce fuel usage by up to 30%.

Coming to consolidating shipments? That alone can cut your per-order cost significantly while reducing emissions. And if you’re using ocean freight, strategies like slow steaming can lower fuel consumption by nearly 27% without needing to mend your operations.

It's honestly a win-win situation because customers love it too.

A recent NielsenIQ report showed 66% of customers are willing to pay more for eco-conscious brands. That means your green efforts aren’t just saving money but are making money by attracting value-driven buyers.

Sustainability in shipping is now a business necessity, not a luxury. From Ikea’s savings to Dell’s smart packaging, the success stories are clear.

Carrier partners like eShipper help your brand make the sustainable leap seamlessly.

As customers expect more and regulations grow tougher, taking action isn’t optional.

Start small, scale with intention, and make sustainability your competitive edge.

A: Turns out that people care! Seventy-three percent of consumers prefer to see eco-friendly options.

Choosing greener packaging is an option to show your values and reduce shipping costs. It's a win-win approach that demonstrates environmental responsibility while potentially lowering your operational expenses.

A: Think smarter, not more expensive: select optimal box sizes, consolidate shipments, and use eco-friendly carriers.

These cost-effective improvements can significantly reduce your carbon footprints! Focus on right-sizing packages, combining orders when possible, and partnering with carriers that prioritize environmental initiatives.

A: UPS, FedEx, and USPS offer a mix of green solutions, from electric vehicle deliveries to carbon offset programs.

Make sure the ones you pick actually do so. Research their specific sustainability commitments, track records, and verify their environmental initiatives align with your business values.

A: They certainly are! That said, those modern eco-mailers really are built to last: water-resistant, tear-proof, and more-than-capable of delivering your packages safely.

Plus, they're a hit with the eco-conscious set. Today's sustainable mailers provide the same protection as traditional options while appealing to environmentally aware customers.

A: Choose FSC-certified boxes relating to high recycled content and are custom-sized for your products.

The best part is they are cost-effective, waste friendly, and add a professional look to your brand. Look for certifications that verify environmental standards and consider boxes that can be easily recycled by your customers.

A: Yes. It is all about using UN-certified, environmentally friendly packaging to stay compliant and to support sustainable practices.

Work with specialized carriers who understand both regulatory requirements and sustainable options for hazardous material shipping to ensure safety and environmental responsibility.

A: Your shipping gives expression to your commitment toward ESG. Do business with carriers who value sustainability, fair labor, and ethical conduct because it is just good business.

ESG-aligned shipping choices can improve your brand reputation, attract conscious consumers, and potentially provide access to ESG-focused investment opportunities.