SARA NAWAB

9 mins read

12 mins read

In today's dynamic global marketplace, the efficient management of supply chains is pivotal for businesses seeking to maintain their competitiveness and meet the ever-evolving demands of consumers. A supply chain, in essence, encompasses all the intricate processes and activities involved in the production, transportation, and distribution of goods and services. In this blog, we embark on an exploration of the significance of streamlined supply chains and the pivotal role played by logistics and technology in realizing this goal.

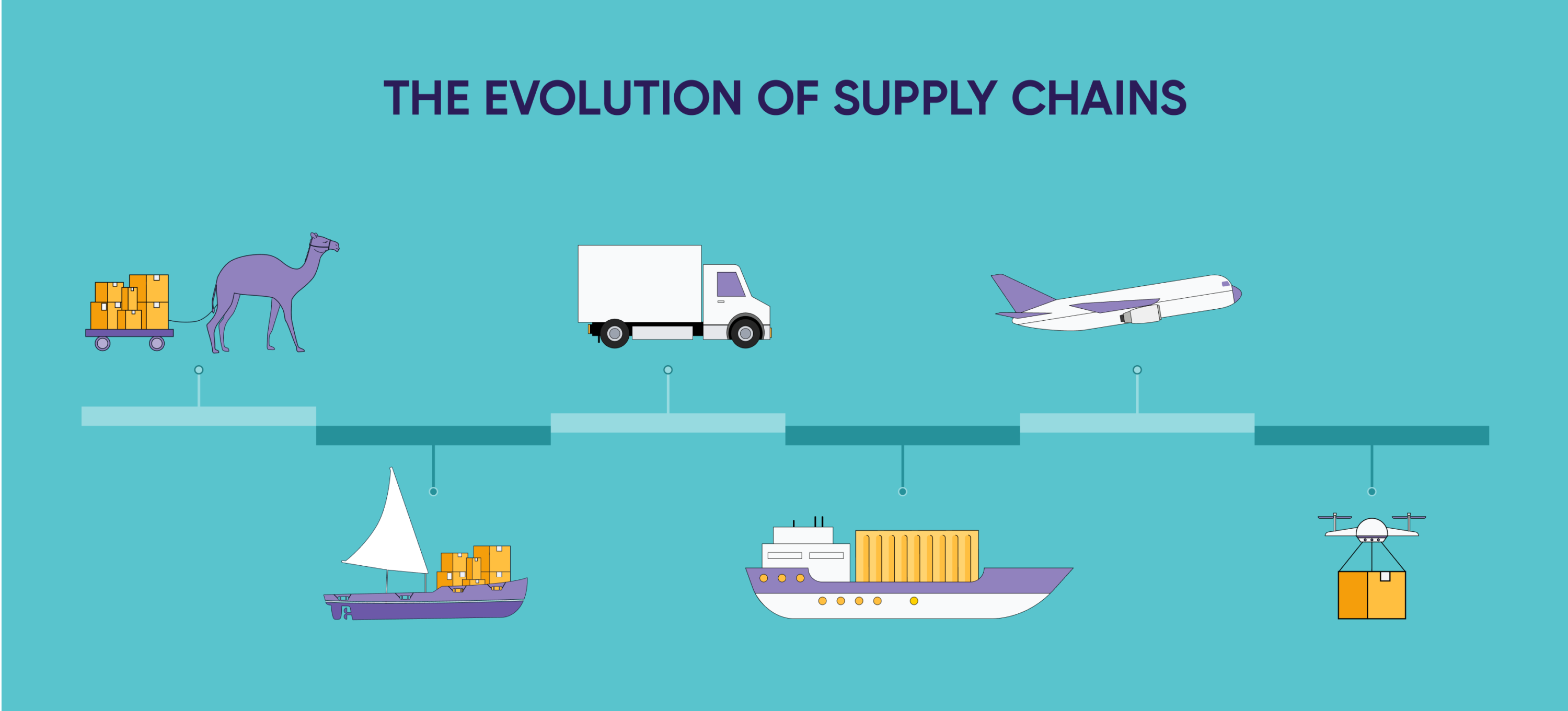

To appreciate the transformative impact of technology on supply chains, it's essential to delve into their historical evolution. Supply chains have been an integral part of human commerce for centuries, evolving from simple barter systems to the intricate and far-reaching networks that exist today.

In ancient times, supply chains primarily revolved around the exchange of goods through caravan routes and maritime trade. Communication was sluggish, relying heavily on physical couriers and handwritten records. The lack of real-time visibility into the supply chain led to inefficiencies and significant challenges in meeting demand fluctuations.

Historically, supply chains grappled with several challenges:

The advent of the Internet of Things (IoT) has ushered in an era of real-time tracking and monitoring within supply chains. IoT devices, equipped with sensors, collect data on the condition, location, and status of assets, including inventory, vehicles, and equipment. This wealth of real-time information enables better decision-making and enhanced supply chain visibility.

For instance, in the food industry, IoT sensors can monitor temperature and humidity levels in refrigerated containers, ensuring the preservation of perishable goods during transit. This real-time data allows stakeholders to proactively address issues, such as temperature deviations before they escalate into costly problems.

Artificial Intelligence (AI) has emerged as a game-changer in supply chain management. AI-powered algorithms analyze vast datasets to predict demand patterns, optimize transportation routes, and enhance decision-making processes. AI analytics software can also be used to strengthen physical security systems, with smart cameras and sensor networks configured to automatically detect and address intrusion events.

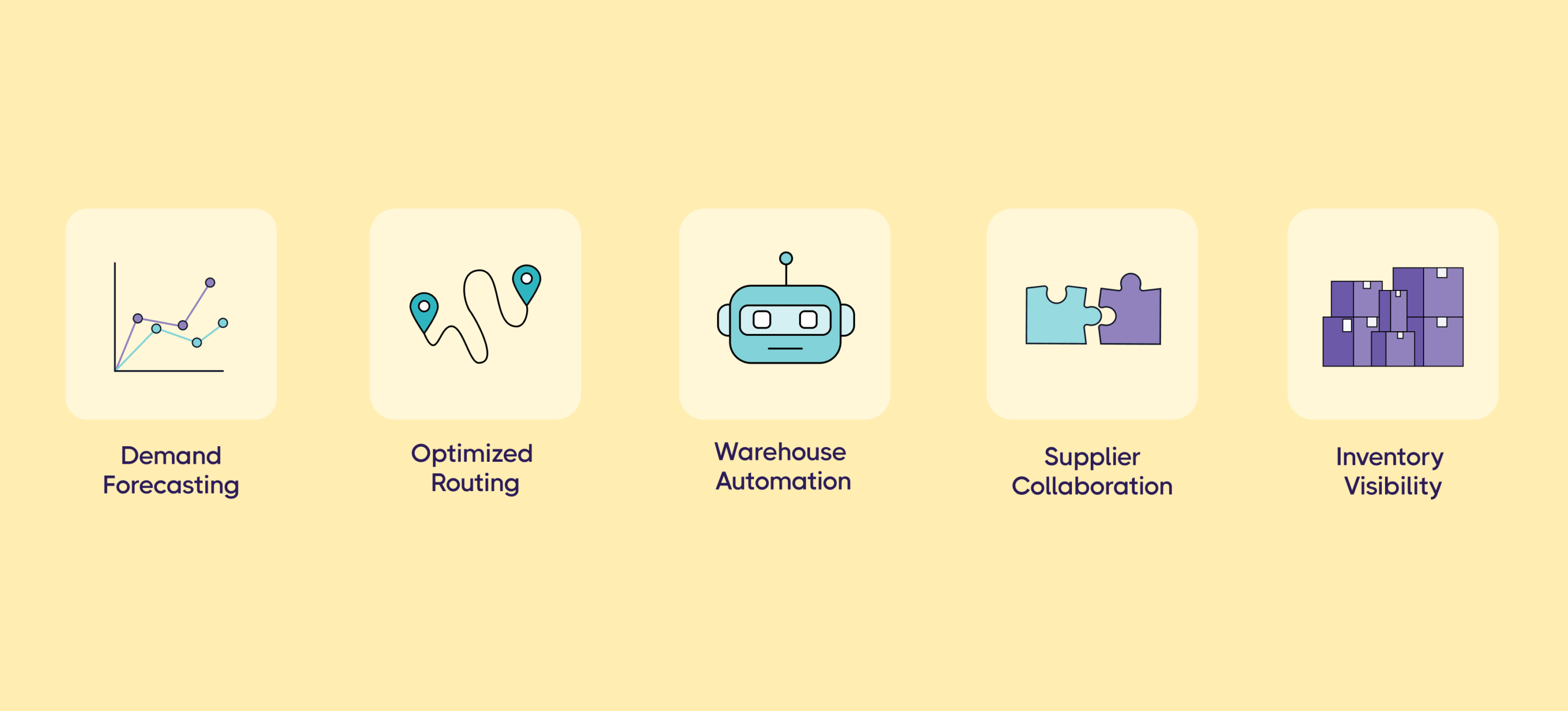

Demand forecasting, a critical aspect of supply chain management, benefits immensely from AI. By considering historical data, market trends, and external factors, AI-driven models provide accurate forecasts, enabling businesses to maintain optimal inventory levels. This reduces the risk of overstocking or stockouts, ultimately enhancing customer satisfaction and cost efficiency.

Blockchain technology has gained prominence for its ability to provide transparency and trust in supply chain transactions. This decentralized and tamper-resistant ledger records every transaction or event within the supply chain, creating an immutable record accessible to all authorized participants.

Blockchain is particularly beneficial in industries where transparency and traceability are paramount, such as food and pharmaceuticals. By scanning a product's QR code, consumers can trace its entire journey from the manufacturer to the store shelves, ensuring authenticity and quality. This transparency not only reduces fraud but also enhances trust among consumers. Blockchain technology also facilitates the implementation of private blockchains, which restrict access to authorized participants, further enhancing data privacy and security within specific supply chain networks

Warehouses are hubs of activity within the supply chain, and the adoption of robotics and automation has revolutionized their operations. Automated systems can efficiently handle tasks like order picking, packing, and sorting, significantly reducing human error and increasing overall efficiency.

Amazon's fulfillment centers provide a notable example of warehouse automation in action. Robots traverse the warehouse, fetching items from shelves and delivering them to human workers for packaging. This streamlined process enables Amazon to fulfill customer orders with remarkable speed and precision.

The proliferation of data in the digital age has paved the way for big data analytics to play a pivotal role in supply chain optimization. With the ability to process vast volumes of data, analytics tools empower organizations to identify trends, make informed decisions, and optimize operations.

For instance, retailers can leverage data analytics to determine the most profitable product assortment for different store locations. By analyzing sales data, customer demographics, and market trends, retailers can tailor their offerings to meet local demand effectively.

One of the primary benefits of technology integration in logistics is the improved visibility and transparency it offers across the entire supply chain. Real-time data and tracking mechanisms enable stakeholders to have a clear view of inventory levels, shipment status, and production progress.

Understanding supply chain management software features can further enhance this visibility, enabling more precise control over operations.

Enhanced visibility allows for better decision-making. When supply chain disruptions occur, businesses can quickly identify the issue's source and take proactive measures to mitigate its impact. This not only reduces operational risks but also enhances overall supply chain resilience.

Accurate demand forecasting is a cornerstone of supply chain success. Technology, particularly AI and big data analytics, empowers organizations to predict demand patterns with remarkable precision. This capability enables businesses to optimize inventory levels, reducing the risk of overstocking or stockouts.

By aligning production and inventory with actual demand, companies can significantly reduce carrying costs while ensuring they have the right products available when customers need them. This, in turn, leads to increased cost efficiency and improved customer satisfaction.

Cost reduction is a central objective of supply chain optimization. Technology-driven solutions, such as automation and AI, help organizations achieve substantial cost savings across various aspects of the supply chain.

For instance, in the logistics and transportation sector, route optimization algorithms minimize fuel consumption and transportation costs while maximizing delivery speed. Additionally, automation in warehouses reduces labor costs and minimizes errors in order fulfillment, further driving down operational expenses.

In today's competitive marketplace, exceptional customer service is a differentiator that can set businesses apart. Streamlined supply chains enabled by technology result in faster and more accurate deliveries, which directly translate into improved customer experiences.

Customers now expect rapid order fulfillment, real-time order tracking, and hassle-free returns. Technology equips businesses to meet these expectations efficiently. For example, eCommerce platforms provide customers with real-time updates on the status of their orders, creating a sense of trust and reliability.

With a clear understanding of the technologies driving supply chain optimization and their associated benefits, it's essential to explore practical steps businesses can take to streamline their supply chains:

By adopting these strategies, businesses can make significant strides in streamlining their supply chains, ultimately improving efficiency, reducing costs, and enhancing customer satisfaction.

Examples of Companies Successfully Leveraging Technology

To illustrate the practical impact of technology on supply chain efficiency, let's delve into a few notable case studies:

Amazon: Amazon has become a global eCommerce giant, in large part due to its advanced supply chain and logistics capabilities. The company uses a combination of robotics, AI, and data analytics to optimize warehouse operations, ensuring swift and accurate order fulfillment. Amazon's commitment to customer satisfaction is evident in its Prime two-day delivery service, made possible by its technology-driven supply chain.

Walmart: Walmart, a retail giant, leverages technology to enhance inventory management and optimize its supply chain. The company utilizes RFID technology to track inventory levels in real-time, allowing for precise stock replenishment. Additionally, Walmart employs data analytics to forecast demand and streamline its distribution network, ensuring that products are available when and where customers need them.

FedEx: FedEx is a global courier and logistics company that relies on technology to manage its vast delivery network. The company uses sophisticated routing algorithms to optimize delivery routes, minimize fuel consumption, and reduce delivery times. Real-time tracking and advanced communication systems provide customers with visibility into their shipments, enhancing their experience.

These examples highlight how technology can lead to significant efficiency gains and improved customer experiences within supply chains.

While the benefits of technology integration in logistics and supply chain management are substantial, several challenges must be addressed:

Implementing new technology solutions can be costly and complex. Businesses need to allocate budgets for hardware, software development, training, and system integration. Additionally, transitioning from existing systems to new ones can disrupt operations temporarily.

With the increased reliance on digital systems and data sharing, ensuring the security and privacy of sensitive supply chain information is paramount. Cyberattacks and data breaches can have severe consequences, including financial losses and reputational damage.

Implementing robust security measures, such as using a password manager to generate and store strong, unique passwords for each system, is crucial for protecting valuable supply chain data and maintaining the integrity of operations.

Adapting to new technology often requires a skilled workforce capable of operating and maintaining these systems. The skills gap can be a significant barrier to technology adoption, necessitating investment in training and development.

Businesses must address these challenges proactively by conducting thorough risk assessments, investing in cybersecurity measures, and providing ongoing training to employees.

Predictions for the Future of Supply Chain Technology

The future of supply chain technology promises continued innovation and transformation:

Sustainable Supply Chains and Green Logistics

As environmental concerns grow, sustainability and green logistics are emerging as critical factors shaping the future of supply chains. Businesses are increasingly adopting eco-friendly practices, such as optimizing transportation routes to reduce emissions, minimizing packaging waste, and sourcing materials responsibly.

Sustainable supply chains not only align with corporate social responsibility objectives but also resonate with environmentally conscious consumers, providing a competitive edge.

In conclusion, the integration of technology into logistics is the linchpin for streamlining supply chains, reducing costs and enhancing customer satisfaction. As businesses navigate the ever-evolving landscape of global commerce, embracing Digital technology-driven solutions becomes not merely a choice but a necessity. The future of supply chains is closely tethered to innovation and adaptation, and those enterprises that seize these opportunities will be best positioned to thrive in the years to come.

A: Supply chain streamlining involves optimizing the processes and operations within a supply chain to reduce costs, improve efficiency, and enhance overall performance.

A: Logistics is a critical component of the supply chain, focusing on the management of goods and information flow from suppliers to consumers.

A: Benefits include increased efficiency, cost savings, improved transparency, and better decision-making.

A: Technologies include IoT, AI, blockchain, robotics, and big data analytics, among others.

A: Streamlining supply chain operations involves optimizing processes, leveraging technology, and improving communication and collaboration with suppliers and partners.

A: The purpose of streamlining is to make supply chain operations more efficient, reduce costs, and enhance overall performance, ultimately delivering better value to customers.